my country is a country with relatively complete non -metal mineral species and rich resources in the world. There are about 56,600 non -metal miners in the country, and the total output value of non -metal mining industry is about 238.2 billion yuan, which has become a non -metal country in the world. With the birth of a large number of emerging industry groups, the production technology has continued to improve, the production process has continued to innovate, and the development of new products is becoming more active. The non -metal mining industry is based on the goal Technology, craftsmanship and equipment innovation. Let's talk about the JZ series ultra -micro crushing classifiers of non -metallic mine processing equipment.

At present, non -metallic mines are diamonds, graphite, kaolin, magnesium ore, diatomic soil, siliconite, calcium carbonate, rigida, Yunmu, gypsum, fluorite, fluorite, fluorite , Limestone, Baiyun Rock, quartz rock, ceramic soil, refractory clay, marble, granite, salt ore, phosphorus ore, etc., and the super -micro -refinement of these non -metal mines, JZ series launched by Youmingke Fan Machinery Co., Ltd. The ultra -micro crushing grading equipment is based on the physical characteristics of non -metallic ore, and the granular particle size is accurately controlled by high -essential gas flow crushing classifiers. According to different measurement, MQW, HTS, and MQL type equipment can be selected. According to the material characteristics, diamonds, graphite, Gangyu and other Mo's hardness can choose MQW series air flow crushing machines, and the hiech can choose the HTS series airflow classifier, kaolin, diatomic earth, calcium carbonate, Yunmu and other MJW series machinery. The type of super microcontroller \u0026 mdash; graded impact grinding.

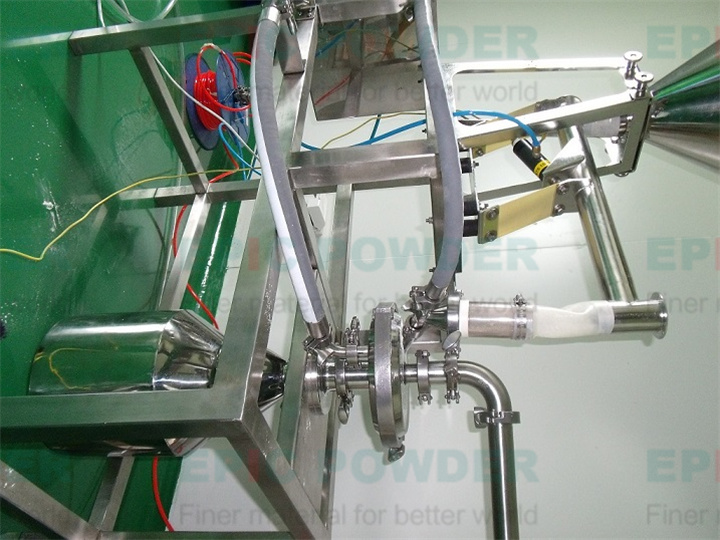

The MJW series airflow crusher uses compressed air through cooling, filtering, and drying, and to form an ultrasonic air flow into the crushing cavity through the nozzle. The intersection of multiple nozzles meets the super fine crushing of particles to achieve a severe impact, collision, friction, and shearing.

The MJW series mechanical ultra -micro crushing machine is a hammer head, blades, rod body, etc. on a high -speed rotation, and impacts the crushed materials. The high -speed impact and rotation of the material between the materials and the cutting and cornering of the stator or the edge wall can be achieved to achieve the purpose of ultra -fine crushing the material. The MQW series airflow crusher and the MJW series mechanical ultra-micro crushing machine can crush the materials to 3-74 microns and can be adjusted arbitrarily. Over the years, Qingdao Youmingke has supplied tens of thousands of (sets) ultra -micro crushing grading equipment and production lines for many non -metal mine processing enterprises at home and abroad. Powder experiments and testing centers can provide free experiments in the early stage.